Continued from Part 1 on THE IMPORTANCE OF LOAD SECURING. Click here to read Part 1.

Tie-down Lashing

Tie-down lashing is the most common type of lashing for the transport of goods over the road. If the cargo is wide (if not wider than the truck tray), securing the load is only possible by vertical or slightly inclined tie-down lashing.

In the case of tie-down lashing, care must be taken to consider factors such as:

Note: Tie-down lashing only works if there is enough friction between the loading area and the load. For example, a steel load on a steel loading area does not offer enough friction which is why wooden supports or anti-slip mats should be used to increase friction.

Diagonal Lashing

For diagonal lashing, two angle plans (horizontal and vertical) should be considered and two angles defined. Diagonal lashing should be prioritised over tie-down lashing. This is because with diagonal lashing, the lashing equipment is not subject to pre-tensioning forces. The lashing equipment is only subjected to higher loads in the event of sudden braking, jerky start, or close cornering.

Are Lifting Points suitable for Lashing?

Lifting points are often installed for lashing purposes. However, lifting points are used primarily for lifting and therefore not marked with the permissible tensile force LC (Lashing Capacity - daN) but with their WLL (tonne). It is important to know that lashing points and lifting points are subject to different design factors. This is why you will find it easier to meet practical requirements with high-strength, tested, and field-proven RUD lashing points.

Weldable RUD lashing points are forged and available in blocks that can be easily welded. RUD lashing points with LC specification in daN can also be retrofitted to the vehicle carrier by certified welders. In addition to these weldable lashing points, RUD also offers an extensive range of boltable lashing points which can be used for load securing.

Tips for Skip Loaders - Optimum Load Securing with Angled Lashing

Load securing is always about the safety of people and the load. Also, having your load secure ensures that you do not run the risk of fines by the transport authorities. With RUD lashing products you be assured of safe transport of your cargo all the time.

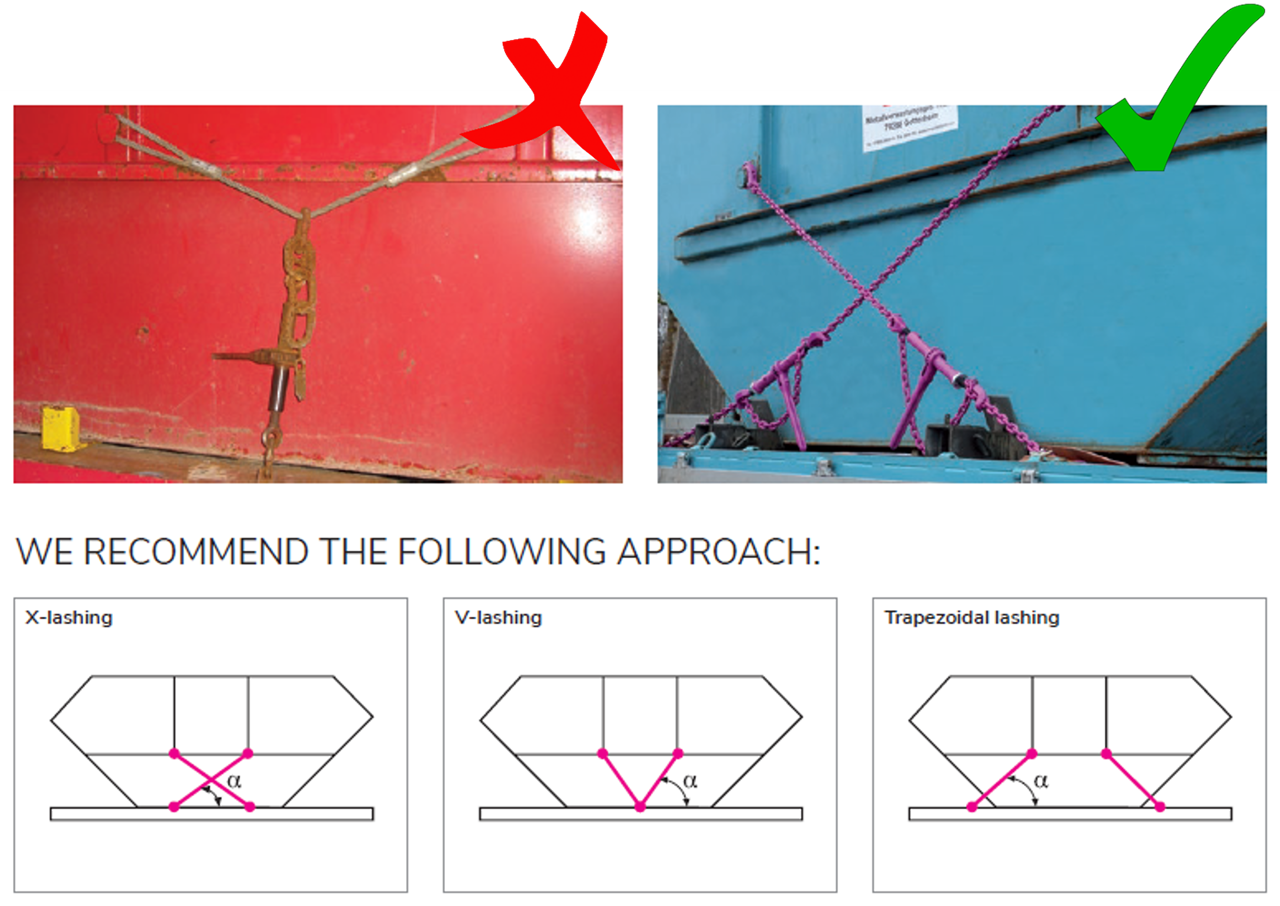

As shown in the pictures, tie-down lashing of trough containers is advisable in V, X, or trapezoidal angles with a fixed connection at the lashing point and the suspension pin. A Y lashing should be avoided because the load will not be adequately secured with this type of lashing.

Finally

If you are transporting heavy machines or cargo, it is important to plan load securing during the design phase components. This means, installing lashing points on both the load and the loading area.

Some of the points to note:

Visit us on Booth #380 (Plaza Level) to know more about our Lifting & Lashing Systems, Workshop Handling Solutions including Endurequip Portalift Hoists and Tyre Protection/Traction Chains.

Article copyright to RUD, this information is accurate at the time of publication and RUD Australia takes no responsibility for any errors inadvertent or otherwise.

If you want to know how the team at RUD can help you, please call 07 3809 1300 or fill out an enquiry form here.

Sources:

When transporting goods or equipment over the road, it is critical to ensure that the goods or equipment is securely fastened. Insecure loads could lead to accidents including human life, and vehicle damage, and also risk to other road users. In addition to the financial and human costs of accidents; there are other significant risks such as liability and negligence claims, criminal prosecution, legal action, higher insurance premiums, and damage to the company’s reputation.

Load Securing

Cargo on a vehicle is subject to acceleration forces when the vehicle on which it is traveling accelerates, brakes, or changes direction. If the cargo on the vehicle is not securely fastened, this means the risk of the cargo moving forward, sliding backward, or tipping sideways is very high. Hence, when a vehicle brakes, the force of momentum will cause the unrestrained cargo to continue moving in its original (forward) direction and thereby cause significant risk of damage to the cargo itself, the vehicle, and possible personal injury to the driver or other road users.

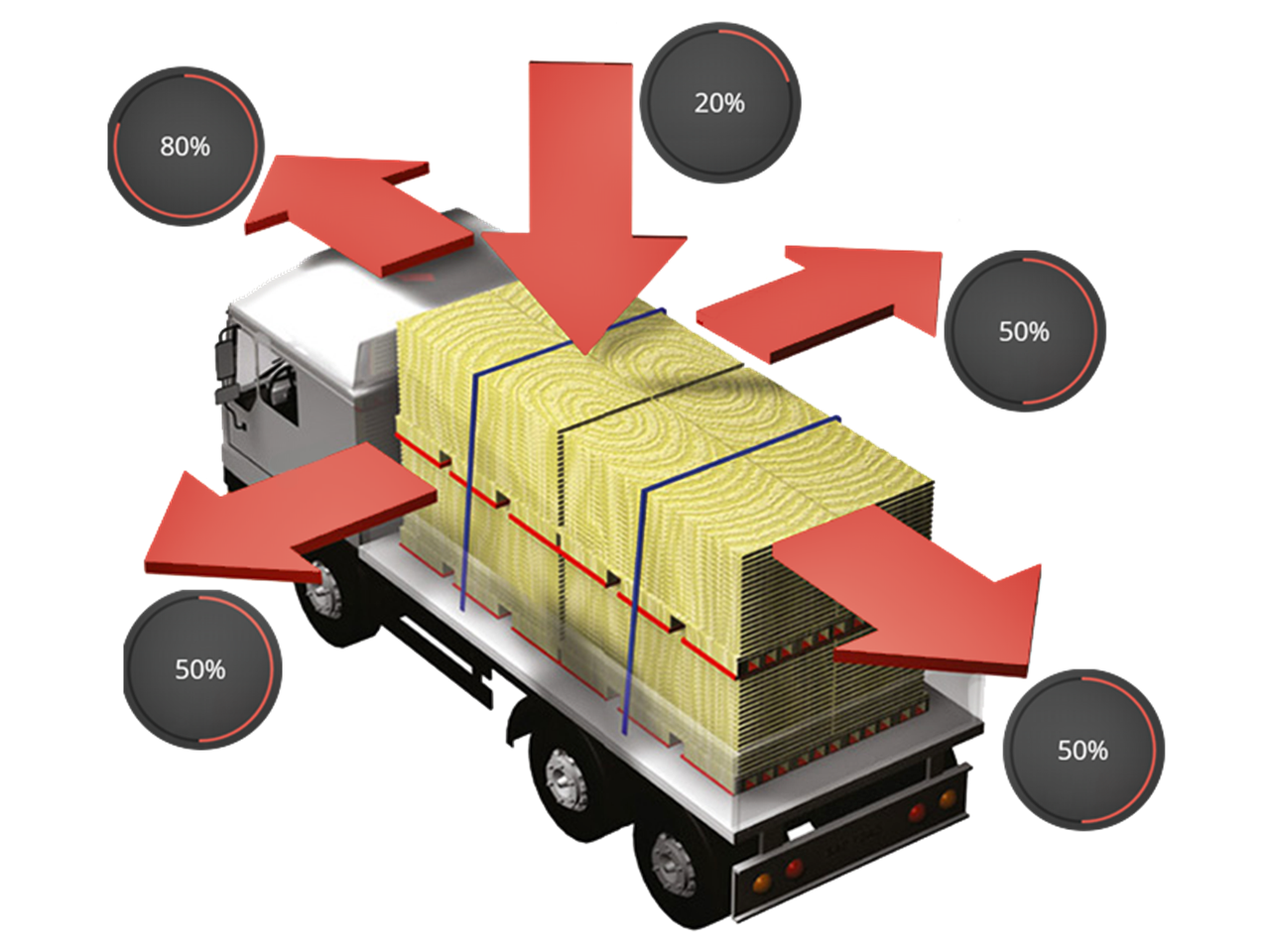

Loaded vehicles are subject to 0.8g deceleration in forward movement, and 0.5g deceleration in both backward and lateral (sideways) directions*. For example, a cargo weighing 10 tonnes is subject to 8 tonnes of forward force and 5 tonnes either sideways or backward. Hence, the cargo must be secured to prevent damage, injury, and risks.

*Australian National Heavy Vehicle Register Load Restraint Guide 2018

Benefits of RUD Lashing Systems

RUD is the world leader and expert in lifting and lashing solutions. All RUD sling products are manufactured exclusively for lifting and load securing using cutting-edge technology. This is why our made-in-Germany innovative products set global standards for the lifting and lashing industry.

RUD offers a range of lashing points and lashing chains for optimal securing of cargo. Some of the popular RUD load-securing products for cargo transport are:

Load securing hints for heavy cargo

One of the solutions to secure heavy cargo is to use RUD lashing chains in double strands.

Endless-Chain Lashing

What happens if there are no lashing points on the cargo to secure the load directly? Using a shackle to connect the lashing chain to unsuitable lashing points is risky because it exposes the shackle to bending stresses. The best option in such cases is to use an Endless Chain that has the same Lashing Capacity (LC) as a lashing chain. And if the chain is “doubled-up”, sharp edges will not cause any problems.

An ICE-Endless-Chain can be used with an ICE-Multi-shortening claw to form a closed chain.

The advantages of such a configuration are:

Without Trucks Australia Stops. But when trucks need to go, Endurequip keeps them going!

Want to meet us?

RUD/Endurequip will be displaying in the Brisbane Truck Show from 18-21 May 2023 at the Brisbane Convention Centre.

Visit us on Booth #380 (Plaza Level) to know more about our Endurequip Hoists, Workshop Lifting/Handling Solutions and Tyre Protection/Traction Chains.

Article copyright to RUD, this information is accurate at the time of publication and RUD Australia takes no responsibility for any errors inadvertent or otherwise.

Sources:

Endurequip Hoists (RUD Australia) visited our service partner Endurequip Services for a chat with the General Manager Pat Ryan and his team to see how we can offer improved services to our customers in 2023.

When you buy Endurequip products, we become part of your business family. You can rely on our highly qualified service technicians and be assured that we have you covered Australia-wide for any support and maintenance.

Endurequip Services has also appointed a technician to cover NSW in 2023.

For more information on Endurequip Hoists, click here to send us an enquiry.