Part 2 of the 2-part article. Click here to read Part 1.

Load securing during transportation faces many challenges, especially when dealing with loads that have sharp edges. The sharp edges pose a risk to the integrity of lashing equipment and can potentially lead to accidents, jeopardising the safety of vehicle occupants and other road users. Hence, understanding the potential dangers associated with sharp edges is critical to ensure safe and efficient transportation. Read Part 2 below.

Reduction of Lashing Capacity

With loads where the lashing chain goes over sharp edges, we recommend reducing the Lashing Capacity (LC) by 25% or using a larger chain size. The Load Restraint Guide 2018 of the National Transport Commission (NTC) outlines the rules for lashing loads with sharp edges.

For example, if a lashing chain has a rated capacity of 10,000 daN, the effective securing capacity with a sharp corner load would be reduced by 25%, to 7500 daN.

ICE Grade 120 Lashing Chains

ICE Grade 120 lashing chain can replace a Grade 80 lashing chain of the next largest nominal thickness in direct lashing. ICE 120 is lighter than Grade 80 by 45% and has a breaking force up to 60% higher than Grade 80. This means that using an ICE 120 lashing chain can result in a large weight reduction, easier assembly, and better safety.

How can Endless Chains help?

In situations where suitable lashing points are unavailable or the existing points are unsuitable, using hooks or shackles for connecting the lashing chain can expose the connecting element to bending stresses. This can compromise the integrity of the connection and lead to potential failure.

Endless chains, designed to eliminate the need for separate hooks or shackles, provide a safer alternative. With an endless chain, the lashing capacity remains consistent throughout the entire chain loop, eliminating the potential weak points associated with hooks or shackles. Moreover, doubling up an endless chain reduces the effects of sharp edges, as the load is distributed across a larger surface area, which limits the stress on individual chain links.

ICE-Endless-Chain and ICE-Multi-shortening Claw

When combined with the ICE-Endless Chain, the ICE-Multi-shortening claw forms a closed chain system that is easily adjustable and can be opened without tools. This flexibility allows for convenient use in situations where the load's dimensions may vary. This configuration is particularly beneficial for securing loads with unconventional shapes, such as stone blocks or concrete, which may lack dedicated lashing points.

The advantages of such a configuration are:

Conclusion:

Understanding and addressing the challenges posed by sharp edges during load securing is crucial for ensuring safe and efficient transportation. By implementing the guidelines of the Load Restraint Guide and utilising appropriate protective measures such as edge protectors and endless chains, we can effectively mitigate the risks associated with sharp edges, ensuring the integrity of the lashing equipment and the safety of all road users.

Article copyright to RUD Group. This information is accurate at the time of publication, and RUD Australia takes no responsibility for any errors, inadvertent or otherwise.

This is a 2 part article.

Load securing during transportation faces many challenges, especially when dealing with loads that have sharp edges. The sharp edges pose a risk to the integrity of lashing equipment and can potentially lead to accidents, jeopardising the safety of vehicle occupants and other road users. Hence, understanding the potential dangers associated with sharp edges is critical to ensure safe and efficient transportation.

Sharp edges can cause considerable wear and tear on lashing equipment, primarily due to the concentrated stress they can impose on the lashing material. The repetitive bending and flexing of the lashing equipment as it goes over these edges can lead to fatigue, weakening the material and potentially causing failure. This failure can result in a sudden snap, a gradual weakening, or a distortion in the equipment's shape, resulting in a compromised load restraint system and a potential safety hazard.

In this article, we will address the question of what is considered a sharp edge and what measures should be taken to ensure safety when working with such angles.

Australian National Transport Commission and sharp edges

The National Transport Commission (NTC), in its Load Restraint Guide 2018, emphasises the importance of protecting lashing chains from sharp edges. This guide outlines a clear correlation between the sharpness of a corner and the chain's lashing capacity, highlighting the critical need to consider the load's geometry when selecting and using lashing equipment.

As per the guide, the lashing chain should be protected over sharp edges or rough surfaces to maintain its full lashing capacity.

When the corner radius (r) is less than the chain size (d), the chain's lashing capacity is reduced by 25%. The above figure is taken from the Australian Load Restraint Guide 2018.

Understanding the Corner Radius and Chain Diameter

When assessing load-securing options, the radius of the sharp edge should be considered in relation to the degree of flexibility of the lashing equipment. The corner radius (r) refers to the radius of the curve at the corner of the load, while the chain diameter (d) refers to the diameter of the chain link. Understanding the relationship between the two is critical because it influences the choice of lashing equipment.

To ensure safe and effective load securing, the corner radius should always be greater than the chain diameter. This ensures smooth chain movement over the corner without any risk of jamming, kinking, or undue stress. When the corner radius is less than the chain diameter, the chain experiences increased bending stress, leading to potential damage and reduced functionality.

Protective measures must be implemented to reduce the risk when the corner radius is smaller than the chain diameter. Edge protectors are an excellent option because they serve as an intermediary between the chain and the load, preventing direct contact and protecting the chain from premature wear and tear.

To be continued ...

Article copyright to RUD Group. This information is accurate at the time of publication, and RUD Australia takes no responsibility for any errors, inadvertent or otherwise.

Continued from Part 1 on THE IMPORTANCE OF LOAD SECURING. Click here to read Part 1.

Tie-down Lashing

Tie-down lashing is the most common type of lashing for the transport of goods over the road. If the cargo is wide (if not wider than the truck tray), securing the load is only possible by vertical or slightly inclined tie-down lashing.

In the case of tie-down lashing, care must be taken to consider factors such as:

Note: Tie-down lashing only works if there is enough friction between the loading area and the load. For example, a steel load on a steel loading area does not offer enough friction which is why wooden supports or anti-slip mats should be used to increase friction.

Diagonal Lashing

For diagonal lashing, two angle plans (horizontal and vertical) should be considered and two angles defined. Diagonal lashing should be prioritised over tie-down lashing. This is because with diagonal lashing, the lashing equipment is not subject to pre-tensioning forces. The lashing equipment is only subjected to higher loads in the event of sudden braking, jerky start, or close cornering.

Are Lifting Points suitable for Lashing?

Lifting points are often installed for lashing purposes. However, lifting points are used primarily for lifting and therefore not marked with the permissible tensile force LC (Lashing Capacity - daN) but with their WLL (tonne). It is important to know that lashing points and lifting points are subject to different design factors. This is why you will find it easier to meet practical requirements with high-strength, tested, and field-proven RUD lashing points.

Weldable RUD lashing points are forged and available in blocks that can be easily welded. RUD lashing points with LC specification in daN can also be retrofitted to the vehicle carrier by certified welders. In addition to these weldable lashing points, RUD also offers an extensive range of boltable lashing points which can be used for load securing.

Tips for Skip Loaders - Optimum Load Securing with Angled Lashing

Load securing is always about the safety of people and the load. Also, having your load secure ensures that you do not run the risk of fines by the transport authorities. With RUD lashing products you be assured of safe transport of your cargo all the time.

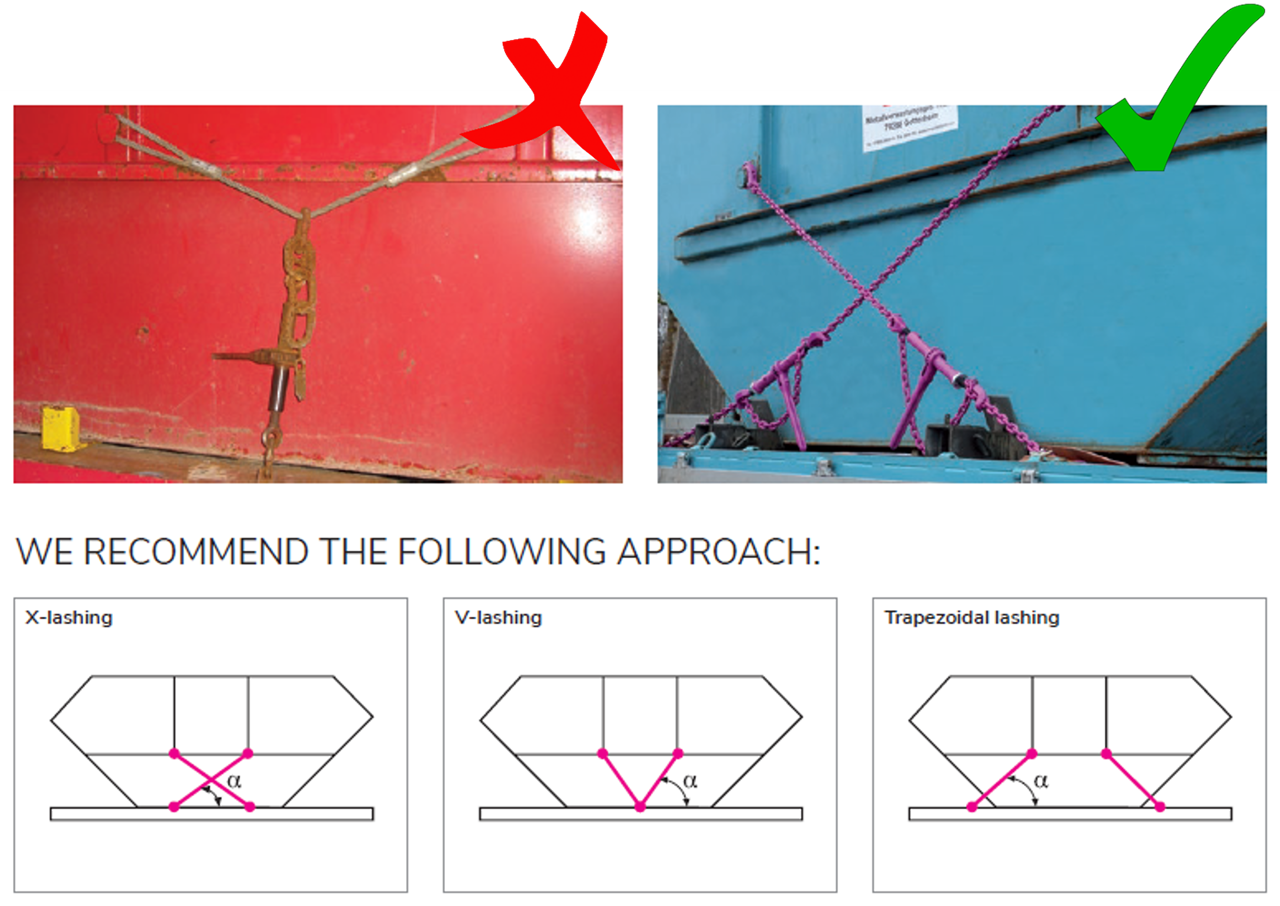

As shown in the pictures, tie-down lashing of trough containers is advisable in V, X, or trapezoidal angles with a fixed connection at the lashing point and the suspension pin. A Y lashing should be avoided because the load will not be adequately secured with this type of lashing.

Finally

If you are transporting heavy machines or cargo, it is important to plan load securing during the design phase components. This means, installing lashing points on both the load and the loading area.

Some of the points to note:

Visit us on Booth #380 (Plaza Level) to know more about our Lifting & Lashing Systems, Workshop Handling Solutions including Endurequip Portalift Hoists and Tyre Protection/Traction Chains.

Article copyright to RUD, this information is accurate at the time of publication and RUD Australia takes no responsibility for any errors inadvertent or otherwise.

If you want to know how the team at RUD can help you, please call 07 3809 1300 or fill out an enquiry form here.

Sources:

When transporting goods or equipment over the road, it is critical to ensure that the goods or equipment is securely fastened. Insecure loads could lead to accidents including human life, and vehicle damage, and also risk to other road users. In addition to the financial and human costs of accidents; there are other significant risks such as liability and negligence claims, criminal prosecution, legal action, higher insurance premiums, and damage to the company’s reputation.

Load Securing

Cargo on a vehicle is subject to acceleration forces when the vehicle on which it is traveling accelerates, brakes, or changes direction. If the cargo on the vehicle is not securely fastened, this means the risk of the cargo moving forward, sliding backward, or tipping sideways is very high. Hence, when a vehicle brakes, the force of momentum will cause the unrestrained cargo to continue moving in its original (forward) direction and thereby cause significant risk of damage to the cargo itself, the vehicle, and possible personal injury to the driver or other road users.

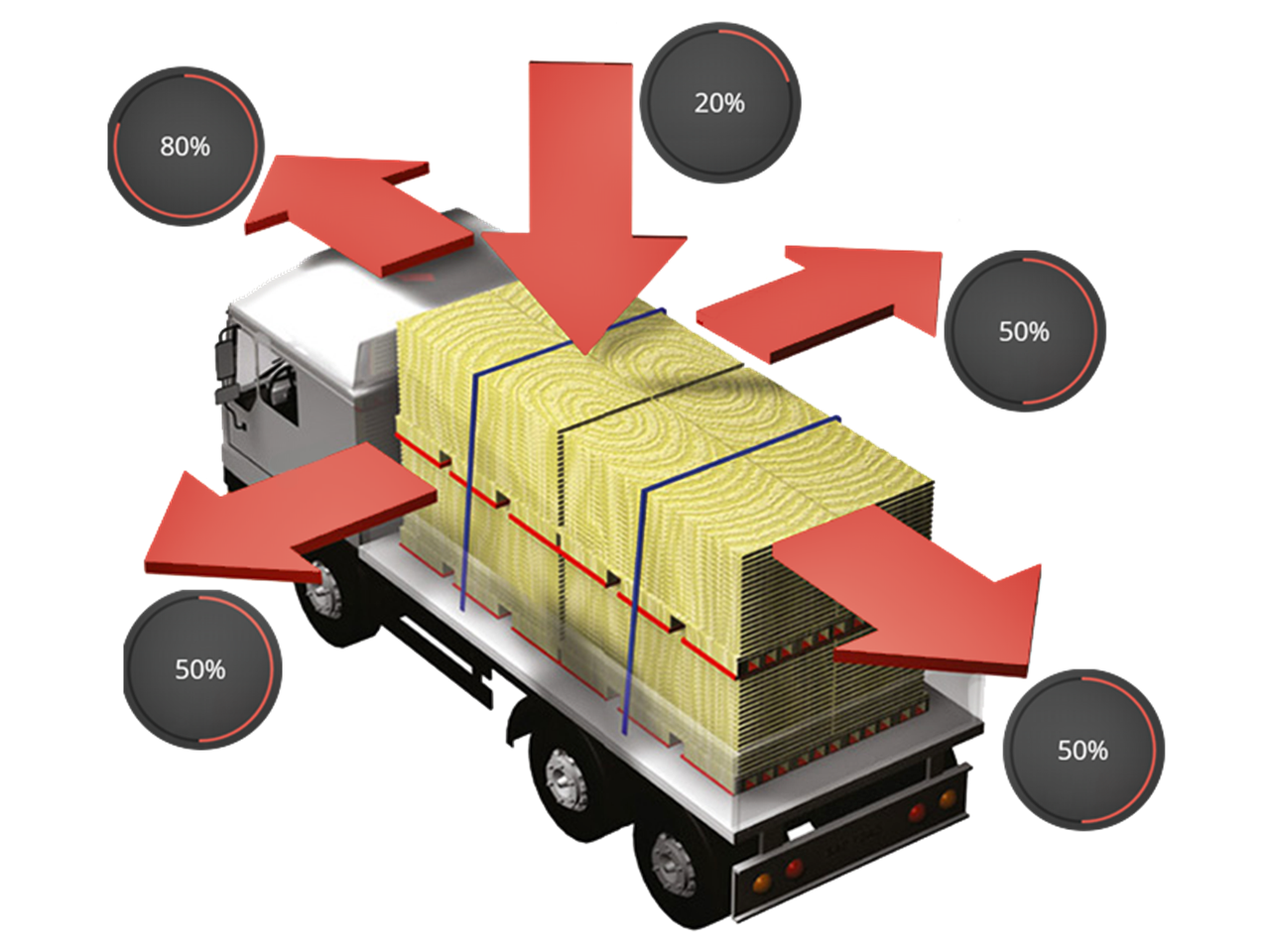

Loaded vehicles are subject to 0.8g deceleration in forward movement, and 0.5g deceleration in both backward and lateral (sideways) directions*. For example, a cargo weighing 10 tonnes is subject to 8 tonnes of forward force and 5 tonnes either sideways or backward. Hence, the cargo must be secured to prevent damage, injury, and risks.

*Australian National Heavy Vehicle Register Load Restraint Guide 2018

Benefits of RUD Lashing Systems

RUD is the world leader and expert in lifting and lashing solutions. All RUD sling products are manufactured exclusively for lifting and load securing using cutting-edge technology. This is why our made-in-Germany innovative products set global standards for the lifting and lashing industry.

RUD offers a range of lashing points and lashing chains for optimal securing of cargo. Some of the popular RUD load-securing products for cargo transport are:

Load securing hints for heavy cargo

One of the solutions to secure heavy cargo is to use RUD lashing chains in double strands.

Endless-Chain Lashing

What happens if there are no lashing points on the cargo to secure the load directly? Using a shackle to connect the lashing chain to unsuitable lashing points is risky because it exposes the shackle to bending stresses. The best option in such cases is to use an Endless Chain that has the same Lashing Capacity (LC) as a lashing chain. And if the chain is “doubled-up”, sharp edges will not cause any problems.

An ICE-Endless-Chain can be used with an ICE-Multi-shortening claw to form a closed chain.

The advantages of such a configuration are:

Without Trucks Australia Stops. But when trucks need to go, Endurequip keeps them going!

Want to meet us?

RUD/Endurequip will be displaying in the Brisbane Truck Show from 18-21 May 2023 at the Brisbane Convention Centre.

Visit us on Booth #380 (Plaza Level) to know more about our Endurequip Hoists, Workshop Lifting/Handling Solutions and Tyre Protection/Traction Chains.

Article copyright to RUD, this information is accurate at the time of publication and RUD Australia takes no responsibility for any errors inadvertent or otherwise.

Sources: